詳細說明

直線(xiàn)模組綜合解說

HIWIN上銀直線(xiàn)模組KA1005P-450A-FR

注意事項

本SR[Single Axis Robot)系列産(chǎn)品屬于機電(diàn)設備,為(wèi)維護使用(yòng)者的安(ān)全,在選擇機型及實際操作(zuò)本産(chǎn)品之前,請務(wù)必詳細閱讀相關型錄及下列注意事項并依照指示使用(yòng),若未依照本注意事項使用(yòng)本産(chǎn)品而造成功能(néng)異常、損壞或其他(tā)事故,本公(gōng)司概不負責。

人身安(ān)全

本産(chǎn)品适用(yòng)于工(gōng)業用(yòng)途,不可(kě)應用(yòng)在直接與人命或人員福祉相關的保安(ān)元件上。

本産(chǎn)品操作(zuò)運轉時,人員應維持在機械動作(zuò)範圍外,以免夾傷或發生其他(tā)工(gōng)安(ān)事故。

本産(chǎn)品接裝(zhuāng)電(diàn)機并通電(diàn)時,裝(zhuāng)置心律調節器者應維持在一公(gōng)尺距離外,以免受到幹擾。

本産(chǎn)品勿裝(zhuāng)置在火源、易燃物(wù)、可(kě)燃氣體(tǐ)附近,以防火災。

儲放與安(ān)裝(zhuāng)

搬運時應避免墜落或碰撞。

儲放本産(chǎn)品時,建議平放并應妥善包裝(zhuāng),避免暴露于高溫、低溫、潮濕的環境。

切勿自行拆解或改裝(zhuāng)本産(chǎn)品,以免異物(wù)進入或産(chǎn)品破壞,造成功能(néng)異常或工(gōng)安(ān)事故。

安(ān)裝(zhuāng)時應将本産(chǎn)品鎖固,以免因振動松脫。

安(ān)裝(zhuāng)聯軸器及電(diàn)機時,須選用(yòng)适當的元件,并注意對準軸中(zhōng)心線(xiàn)後将螺絲鎖固,切勿強行安(ān)裝(zhuāng)。

操作(zuò)使用(yòng)

操作(zuò)時須依照型錄記載的額定條件,例如最高轉速、負荷等,以免造成功能(néng)損壞或工(gōng)安(ān)事故。

應避免粉塵、切屑等異物(wù)侵入滾珠循環系統内,造成損壞、壽命減短或功能(néng)異常。

操作(zuò)環境溫度應在80°C以下,若需應用(yòng)在高溫場所的産(chǎn)品,請洽HIWIN業務(wù)。

環境特殊時,例如強大振動、真空室、無塵室、腐蝕性化學(xué)物(wù)、有(yǒu)機溶劑或藥劑、極高溫或低溫、潮濕濺水、油滴油霧、高鹽分(fēn)、重負荷、垂直或懸臂安(ān)裝(zhuāng)等,請先洽HIWIN業務(wù)确認本産(chǎn)品适用(yòng)條件。

垂直安(ān)裝(zhuāng)時,負載有(yǒu)墜落的危險,建議加裝(zhuāng)适當的煞車(chē),并于使用(yòng)前确認煞車(chē)功能(néng)正常。

維護

初次使用(yòng)前應先将潤滑油補滿,請注意油品種類,不同的潤滑油不可(kě)混用(yòng)。

正常使用(yòng)狀況下,建議每行走100km應檢查運轉狀況一次,清除積污,并補充潤滑油,導軌及絲杠均應潤滑。

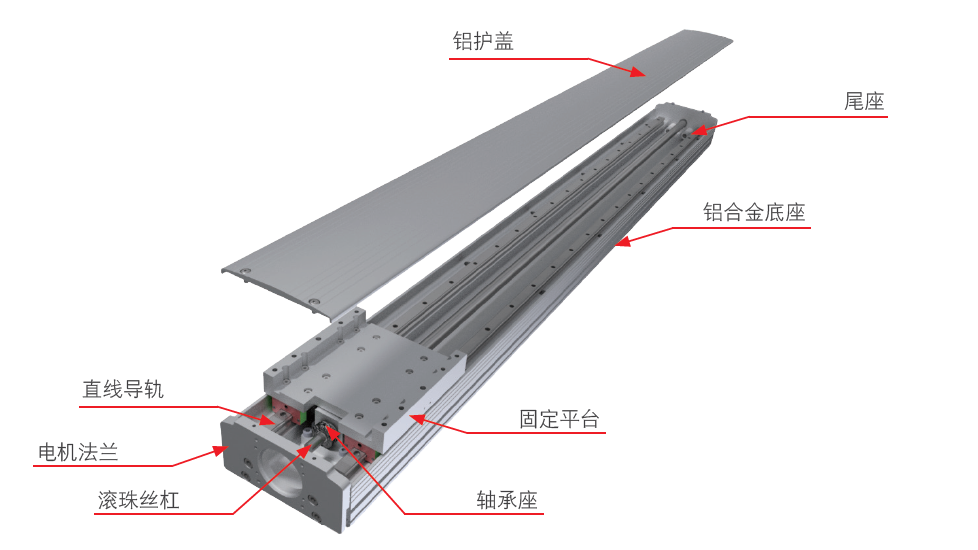

綜合解說

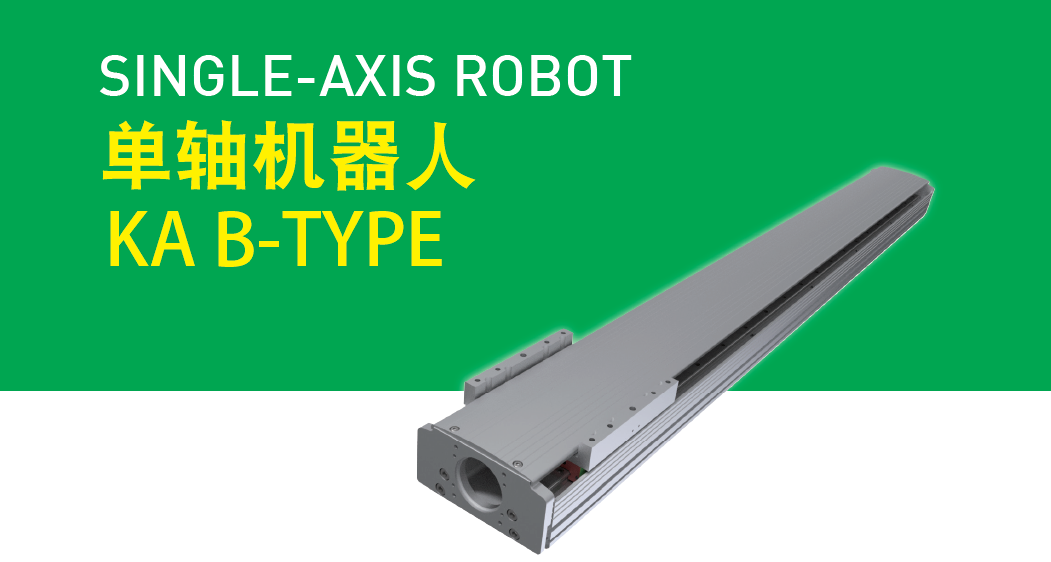

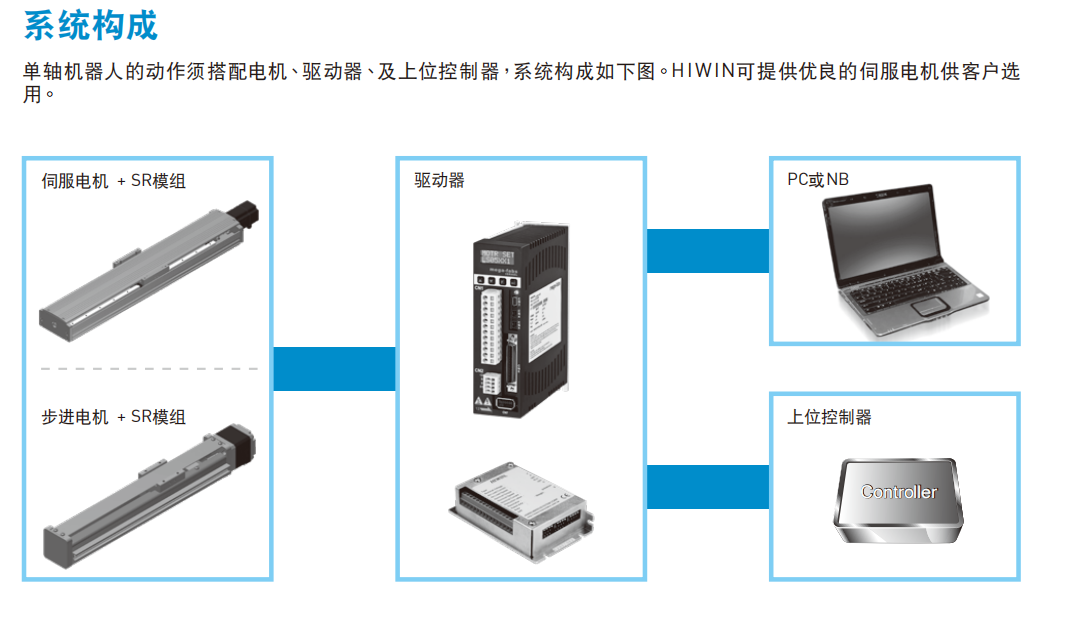

HIWIN單軸機器人模組,系利用(yòng)多(duō)年來的制造技(jì )術與專業水準,配合自行研發生産(chǎn)的滾珠絲杠與直線(xiàn)導軌設計之模組,具(jù)有(yǒu)安(ān)裝(zhuāng)容易、體(tǐ)積小(xiǎo)高精(jīng)度等特點,産(chǎn)品種類規格多(duō)樣化,适用(yòng)于各類自動化設備。

産(chǎn)品特色

産(chǎn)品多(duō)樣化,可(kě)搭配需要選用(yòng):

驅動方式:可(kě)分(fēn)滾珠絲杠、時規皮帶.

電(diàn)機出力:可(kě)自行選配伺服電(diàn)機,或步進電(diàn)機

電(diàn)機連結:直接、下接、内藏、左接、右接,依使用(yòng)空間而定

有(yǒu)效行程: 100~2000mm ( 依絲杠轉速限制)

組裝(zhuāng)與維護容易

可(kě)依顧客需要作(zuò)客制化、單件或組合件的特殊設計制造

單軸可(kě)組合成多(duō)軸使用(yòng)

電(diàn)機法蘭座、電(diàn)機與聯軸器安(ān)裝(zhuāng)注意事項

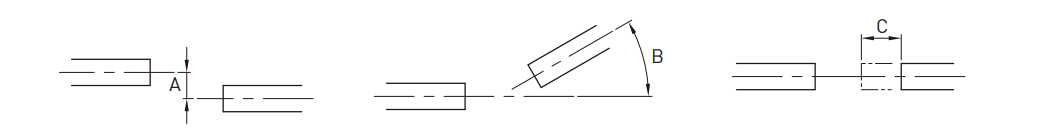

絲杠肩部與電(diàn)機軸兩軸組裝(zhuāng)時,須注意以下三種基本偏差,說明圖示如下:

1.偏心[A): 2.偏角[B): 3.軸向位移[C]:

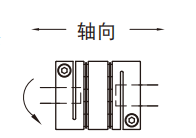

兩軸中(zhōng)心線(xiàn)簡易校準确認方式,可(kě)将位于絲杠肩部與電(diàn)機軸間的聯軸器處于松動狀态下,轉動聯軸器,确認聯軸器是否能(néng)夠沿軸向旋轉方向輕輕移動,以确認兩軸心的同心度,說明圖示如右:

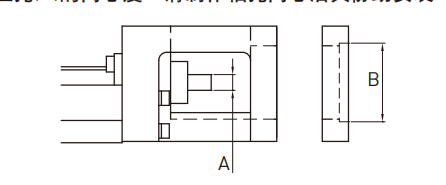

絲杠肩部(A)與電(diàn)機法蘭座定位孔(B)的同心度,請制作(zuò)軸孔同心治具(jù)協助安(ān)裝(zhuāng), 說明圖示如下:

安(ān)裝(zhuāng)注意事項:

1.電(diàn)機法蘭座安(ān)裝(zhuāng)時,請注意電(diàn)機法蘭座定位孔與絲杠肩部的偏差需在聯軸器相關容許偏差值内。

2.絲杠肩部與電(diàn)機軸兩軸的偏差過大時,仍強行裝(zhuāng)上聯軸器,會造成聯軸器或絲杠肩部斷裂的情況産(chǎn)生,所以請确認兩軸的偏差是在聯軸器可(kě)以容許偏差值内。

3.選用(yòng)聯軸器時,建議選擇可(kě)吸收偏心、偏角與軸向位移的撓性聯軸器。

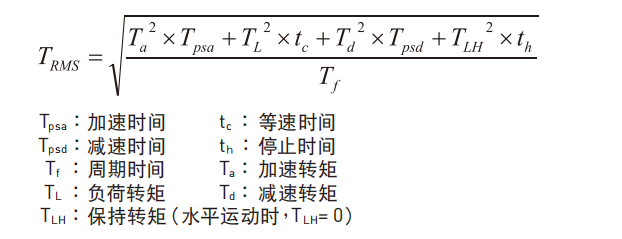

産(chǎn)品應用(yòng)

SR系列産(chǎn)品用(yòng)途廣泛,一般自動化設備均可(kě)應用(yòng),舉例如下:

自動錫焊機、鎖螺絲機、料架零件盒取放、小(xiǎo)型堆棧、黏膠塗布機、零附件取放搬運、CCD鏡頭移動、自動噴漆機、自動上下料裝(zhuāng)置、切割機、電(diàn)子元件生産(chǎn)設備、小(xiǎo)型裝(zhuāng)配線(xiàn)、小(xiǎo)型壓台、點焊機、表面複膜制程、自動貼标簽機、液料灌注分(fēn)裝(zhuāng)、零附件檢驗設備、生産(chǎn)線(xiàn)工(gōng)件整理(lǐ)、材料充填裝(zhuāng)置、包裝(zhuāng)機、刻印機、輸送帶移位、工(gōng)件清潔裝(zhuāng)置等等。

精(jīng)度

精(jīng)度包含準确度(Accuracy)與精(jīng)密度(Precision),如下說明:

1.定位精(jīng)度(準确度)

模組由基準點沿一方向移動,最後實際到達的距離與原設定到達的距離的最大差異值(絕對值)稱之。

2.往返位置重現性(精(jīng)密度)

或指定位重現性,表示SR滑台往返移動過程中(zhōng),在某-設定位置測得的位置差異值,以全行程中(zhōng)的最大值稱之。

3.行走平行度

(1)指SR模組的滑台平面與模組安(ān)裝(zhuāng)平面之間的平行度。量表架于滑台平面中(zhōng)央,指針置于安(ān)裝(zhuāng)平面上,取全行程量

測的最大差異值。

(2)指SR模組的滑台與模組安(ān)裝(zhuāng)基準面之間的平行度。量表架于滑台平面中(zhōng)央,指針置于模組側邊安(ān)裝(zhuāng)基準面上,取

全行程量測的最大差異值。

速度

1.最大線(xiàn)速度

SR滑台最大線(xiàn)速度(V)系由滾珠絲杠最高轉速(S)乘以導程(L)計算而得。

V (mm/sec) =S (rpm)六60XL (mm)

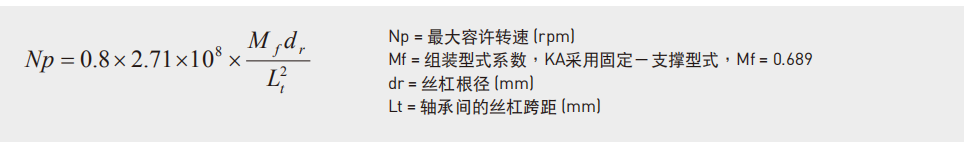

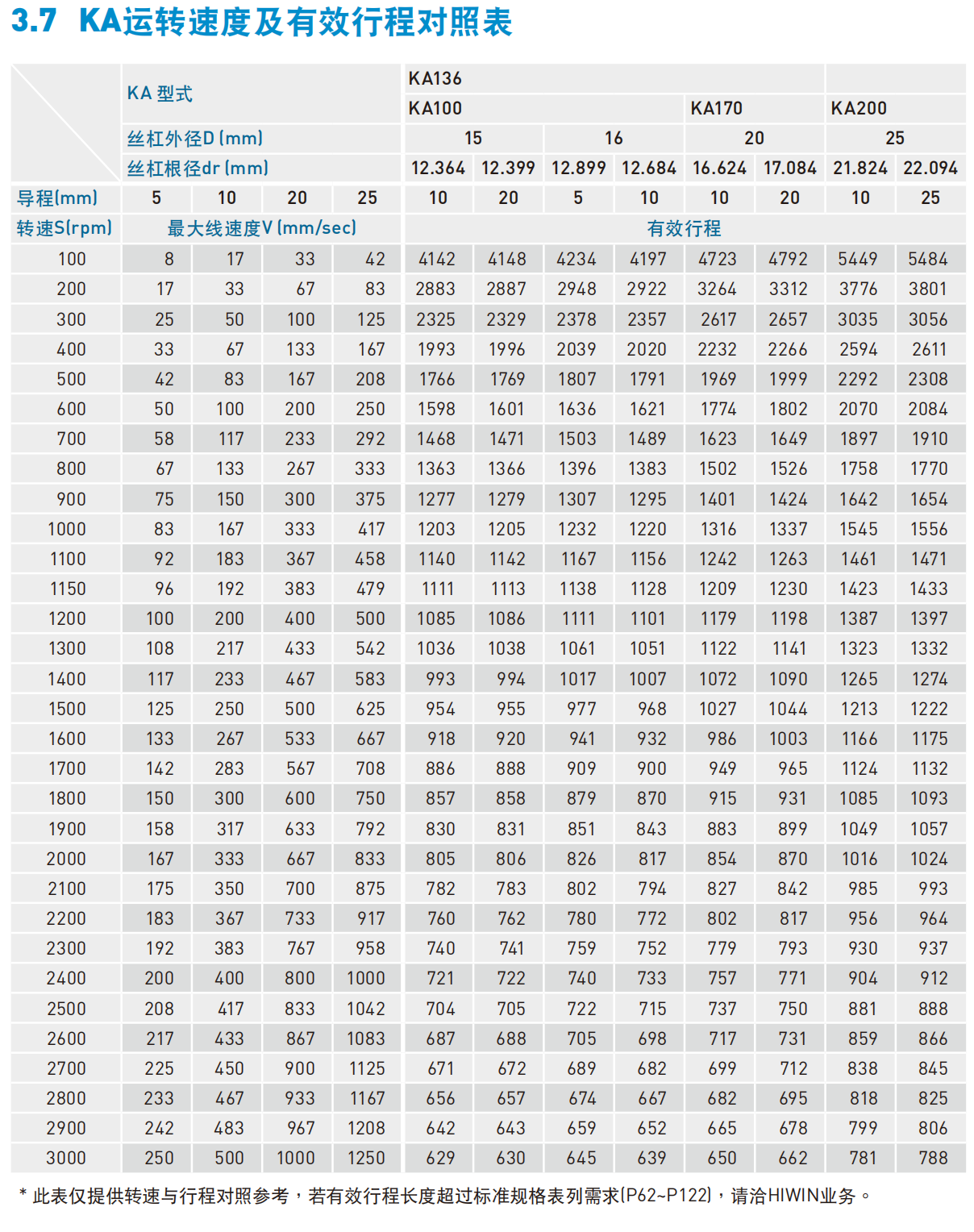

2.最高轉速

表示滾珠絲杠的最大容許轉速,由其臨界轉速而定o絲杠轉速超過臨界轉速時将可(kě)能(néng)發生共振。臨界轉速和絲杠長(cháng)度有(yǒu)關,因此,滾珠絲杠的臨界轉速也間接決定了産(chǎn)品的有(yǒu)效行程和總長(cháng)度。滾珠絲杠的最大容許轉速計算方式如下:

3.加減速度

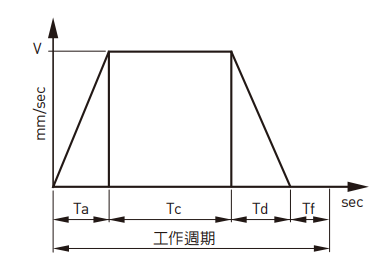

所謂速度系指滑台設定的運轉工(gōng)作(zuò)速度,滑台須自停止狀态開始加速,達工(gōng)作(zuò)速度後維持該速度往目的地移動,抵達.前開始減速,終至停止。

加減速度由使用(yòng)者依實際使用(yòng)需要而定。SR設計時,加速度的設定:導程5以下以0.15G計算,其他(tā)導程均以0.3G計算。1G=9.8m/s2,則0.15G=1470mm/s2,0.3G=2940mm/s2。SR模組最大可(kě)搬質(zhì)量須依加速度而定。

*注意:加減速度将使搬運的質(zhì)量産(chǎn)生慣性負荷,加減速度愈大,可(kě)搬質(zhì)量愈小(xiǎo);過大的加減速度會産(chǎn)生大的沖擊力, 應避免之。

4.工(gōng)作(zuò)周期

工(gōng)作(zuò)周期由客戶依實際需要決定。常用(yòng)工(gōng)作(zuò)周期如下圖所示,包括加速時間Ta、等速時間Tc、減速時間Td、停留時間Tf。

加速度=V/Ta

減速度=V/Td

工(gōng)作(zuò)周期(sec) = Ta+ Tc+ Td+ Tf

工(gōng)作(zuò)時間=工(gōng)作(zuò)周期X次數

運轉率=工(gōng)作(zuò)時間/ (工(gōng)作(zuò)時間+停機時間)

運轉率須配合電(diàn)機負荷而定,通常不宜長(cháng)時間連續不停的工(gōng)作(zuò),建議以0.5為(wèi)準。

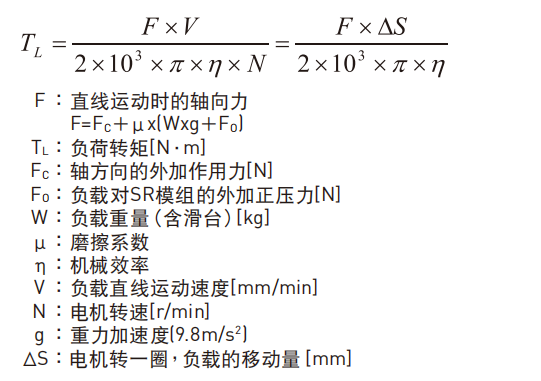

電(diàn)機負載計算

1.确認負載機構的運動條件要求,包括加減速度,運動速度,機構的重量,機構的運動方式。

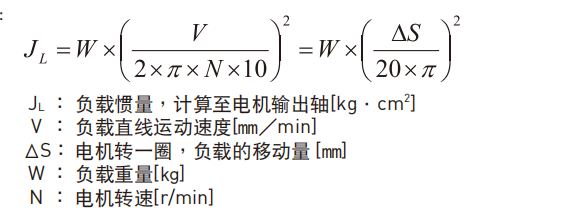

2.負載之慣量計算

直線(xiàn)運動負載慣量計算式:

3.由負載慣量與電(diàn)機慣量的比例原則,選出适當的電(diàn)機規格。

4.将選定的電(diàn)機慣量合并負載慣量,計算出加速轉矩及減速轉矩。

5.依據負載重量,安(ān)裝(zhuāng)方式,磨擦系數,電(diàn)機效率,計算出等速運動時的負荷轉矩。

6.選定電(diàn)機的最大輸出轉矩,須大于加速轉矩和負荷轉矩相加的和;如果不符合條件,必須選用(yòng)其他(tā)型号,再計算驗證至符合要求為(wèi)止。

7.依據負荷轉矩、加速轉矩、減速轉矩及保持轉矩,求出連續實效轉矩。

8.選定電(diàn)機的額定輸出轉矩必須大于連續實效轉矩;如果不符合條件,必須選用(yòng)其他(tā)型号,再計算驗證至符合要求為(wèi)止。

安(ān)裝(zhuāng)

滾珠絲杠型式若确定用(yòng)途為(wèi)垂直方向(z軸)請注意,垂直安(ān)裝(zhuāng)屬于特殊使用(yòng)狀态,承載負荷請在表列最大可(kě)搬重量(直立)範圍内使用(yòng),除此之外,時規皮帶型式禁止垂直方向使用(yòng)。

*注意:為(wèi)防止負載滑落,垂直安(ān)裝(zhuāng)時,采用(yòng)電(diàn)機宜含煞車(chē)。

壽命

于水平安(ān)裝(zhuāng)、側挂安(ān)裝(zhuāng)、傾斜安(ān)裝(zhuāng)(角度小(xiǎo)于30度)時,SR壽命以直線(xiàn)導軌的壽命為(wèi)準;垂直安(ān)裝(zhuāng)、傾斜安(ān)裝(zhuāng)(角度大于30度)時,SR壽命則以絲杠或固定端軸承壽命(取其小(xiǎo)者)為(wèi)準。

表列額定動負載(Fy, Fz, Mx, My, Mz)是相對于模組行走10,000 Km的壽命,若負載小(xiǎo)于表列可(kě)負載條件(Fy/Fyd +Fz/Fzd + Mx/Mxd + My/Myd + Mz/Mzd≤1)則壽命将可(kě)延長(cháng);反之,如果負載大于表定值,則壽命将少于10,000 Km。

為(wèi)确保SR的長(cháng)期使用(yòng),建議盡可(kě)能(néng)在表列負載範圍内使用(yòng)。

保養

SR模組需要維修保養的部分(fēn)包括滾珠絲杠、直線(xiàn)導軌及相關配件。每三個月或每行走100公(gōng)裏的距離後,必須對滾珠絲杠和直線(xiàn)導軌補充潤滑劑,并請檢查有(yǒu)無任何污垢或碎屑在系統内,如果油脂變得肮髒時,請更換油脂。如有(yǒu)任何保養方面的特殊問題,請與HIWIN聯絡。

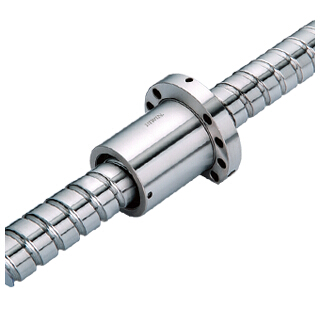

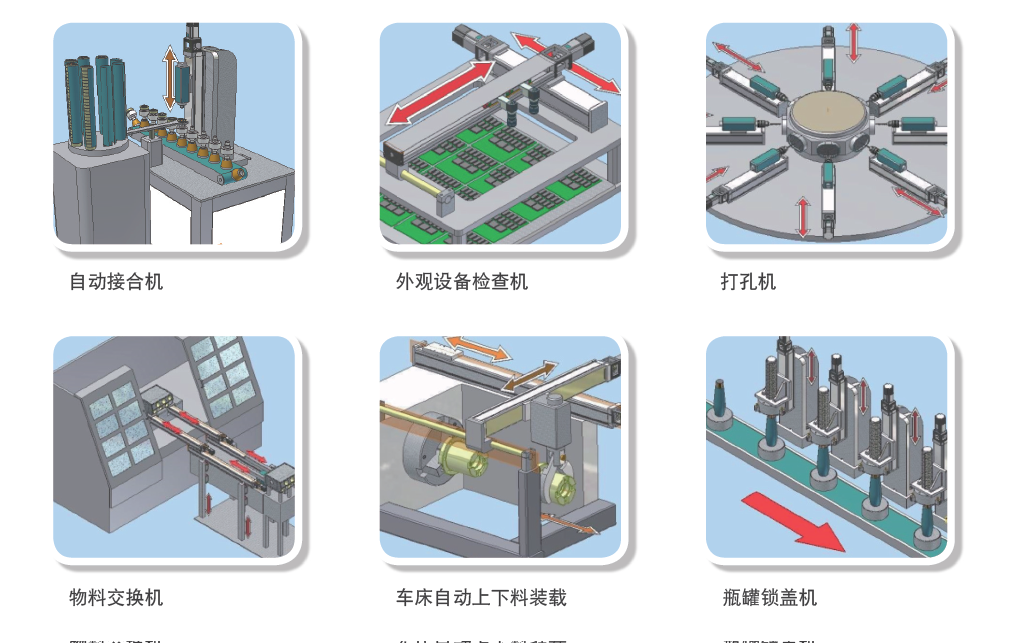

HIWIN上銀(直線(xiàn)模組)單軸機器人-KA型

KA1005P-450A-FR

産(chǎn)品特色/

●驅動系統:可(kě)搭配伺服電(diàn)機或步進電(diàn)機驅動

●運動精(jīng)度:最高可(kě)達±0.01mm

●速度:根據需求,最高可(kě)達1000mm/s ([導程:20mm,轉速:3000RPM)

●防護:鋁護蓋設計可(kě)防止異物(wù)進入,避免異物(wù)卷入造成故障或發生危險

●節省安(ān)裝(zhuāng)空間,總長(cháng)縮短17.2% [注1]

●負荷能(néng)力提升31.6% [注2]

●安(ān)裝(zhuāng)便利性佳,底座同步對應螺紋孔、貫穿孔

●縮短行程位置起點,增加空間利用(yòng)率

*注1 :比較基礎為(wèi)KAA-TYPE,各規格總長(cháng)最大差異17.2%

*注2 :比較基礎為(wèi)KA136 A-TYPE,線(xiàn)軌正向力承載性能(néng)提升31.6%

特征

安(ān)裝(zhuāng)與維護容易

低價格

高鋼性

高重現精(jīng)度±0.01mm

内置AC伺服馬達(選配)

客制化行程

應用(yòng)

高精(jīng)密産(chǎn)業

FPD産(chǎn)業

自動送料機構

自動化視覺檢測

自動化組裝(zhuāng)與點膠

電(diàn)路闆雕刻設備

自動接合機

外觀設備檢查機

打孔機

物(wù)料交換機

車(chē)床自動上下料裝(zhuāng)載

瓶罐鎖蓋機

規格:

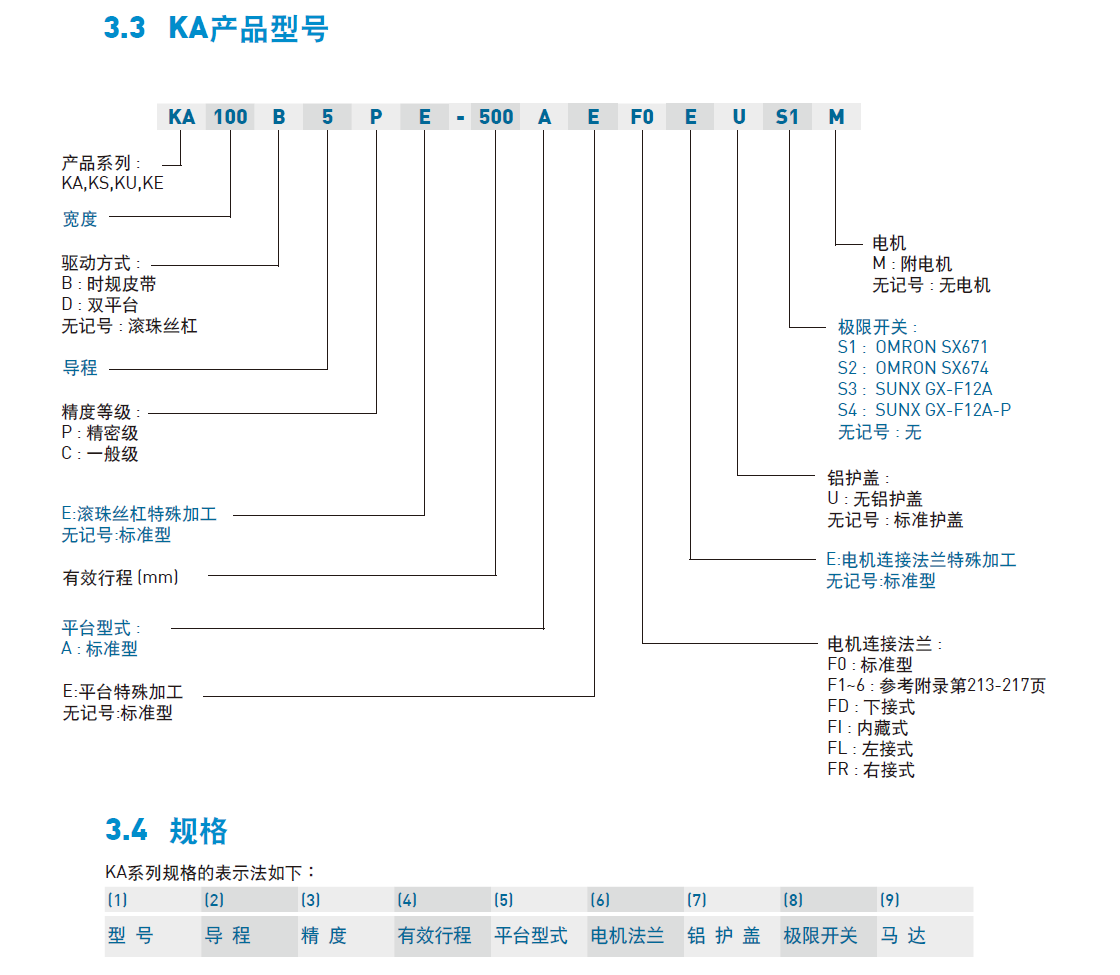

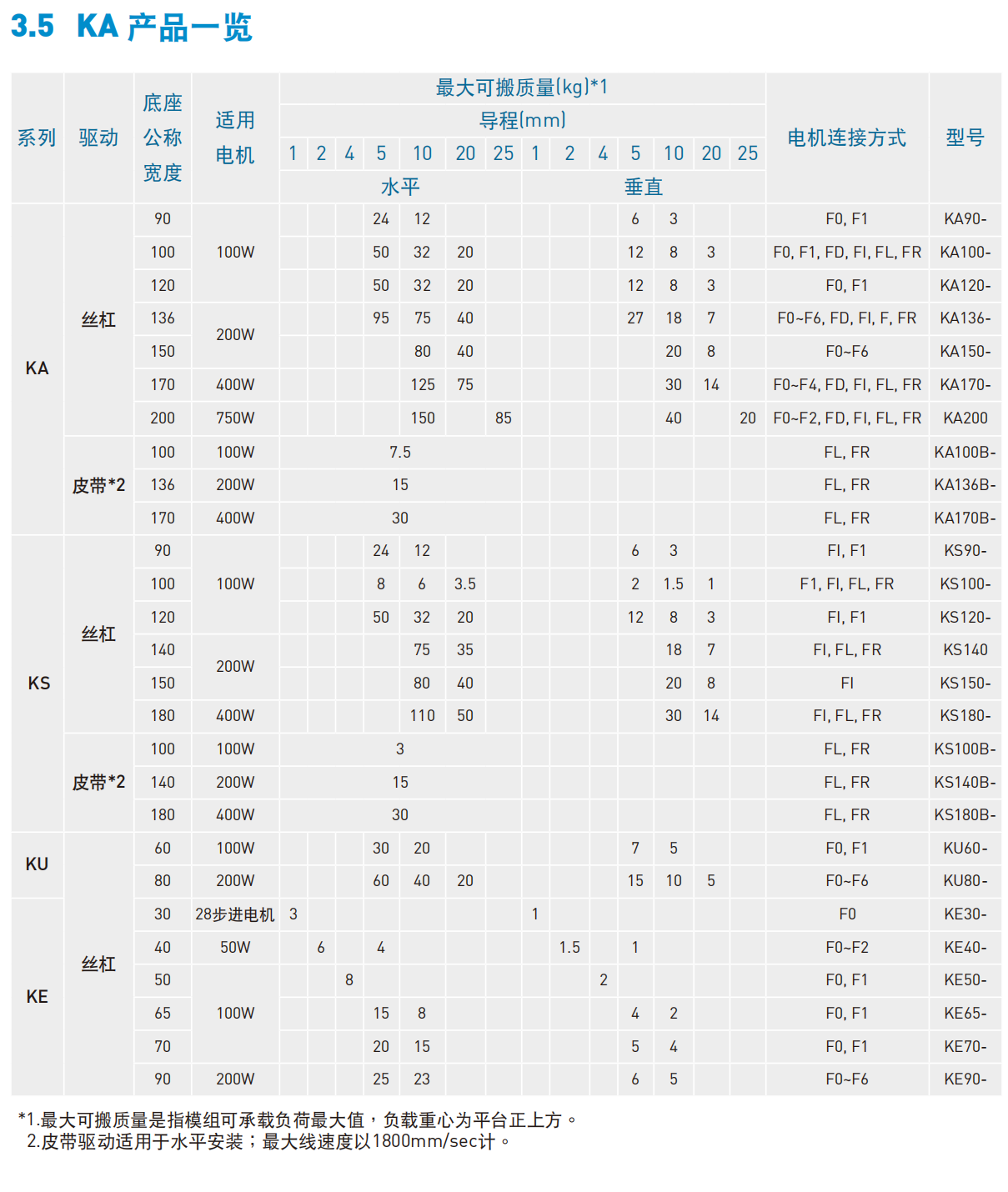

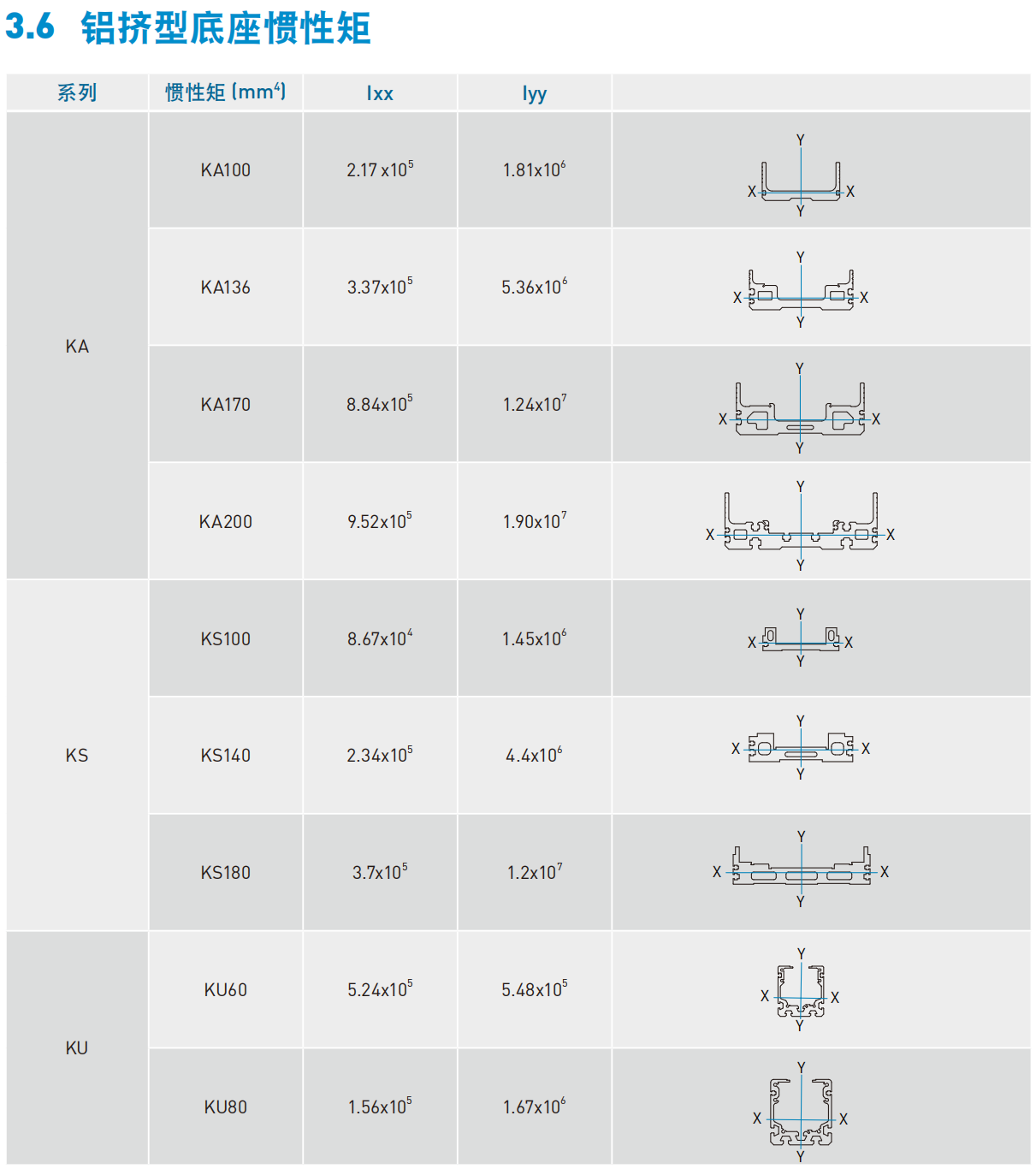

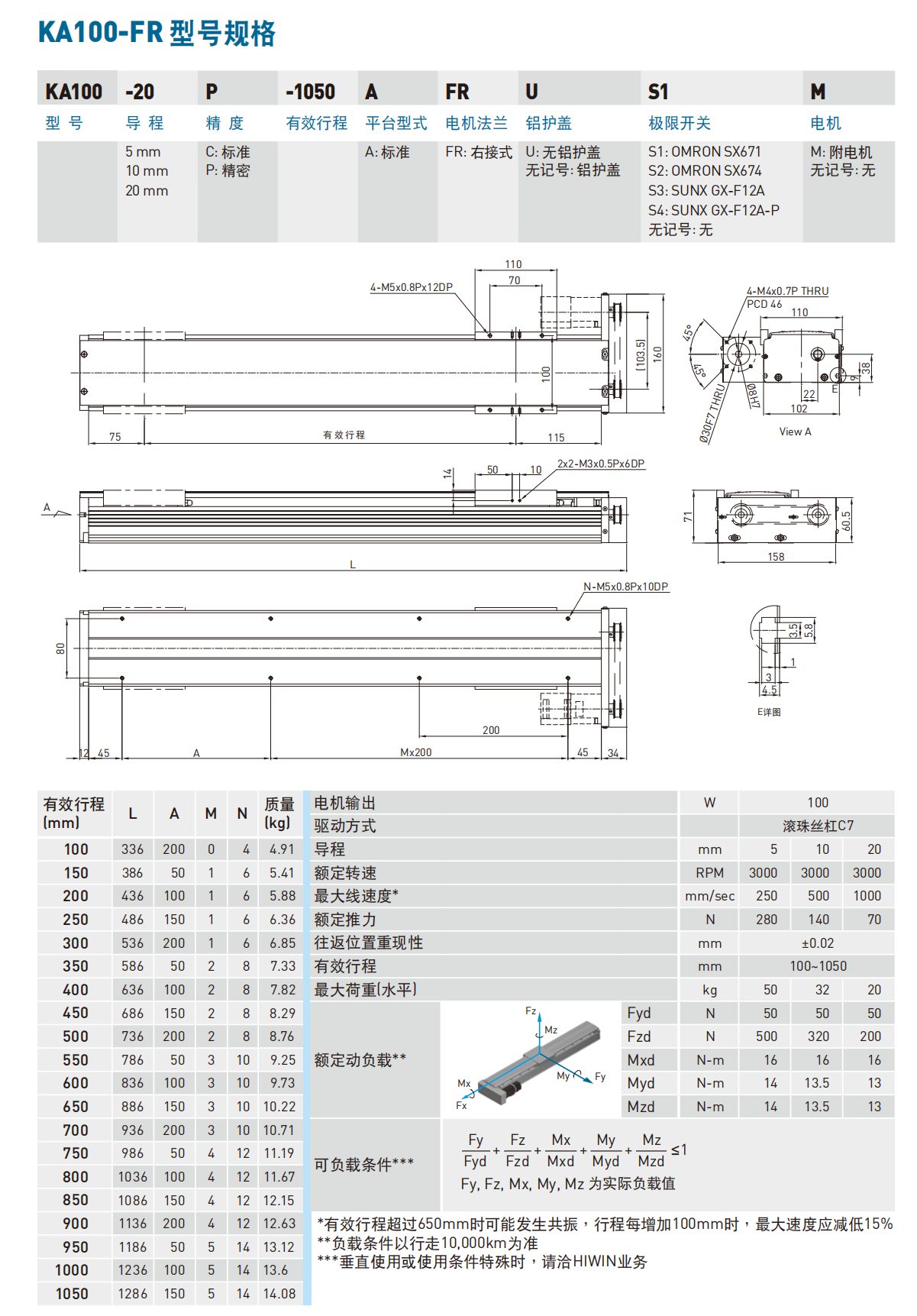

KA系列規格的表示法如下:

①型号:

表示KA系列各型号,數字表示鋁擠型底座公(gōng)稱寬度C

②導程:

表示滾珠絲杠的導程,單位mm,即絲杠旋轉一圈滑台移動的距離。目前KA可(kě)用(yòng)絲杠導程如下:

③精(jīng)度:

表示KA往返位置重現性的精(jīng)度。滾珠絲杠型式的重現精(jīng)度為(wèi)C :标準級=±0.02mm,P :精(jīng)密級=±0.01mm。時規

皮帶型式重現精(jīng)度為(wèi)C :标準級=±0.1mm。

往返位置重現性表示KA滑台往返移動過程中(zhōng),到達某一定點位置的誤差 ,取全行程中(zhōng)誤差的最大值。

*注意: KA産(chǎn)品并未标示絕對定位精(jīng)度。

④有(yǒu)效行程:

表示KA滑台的移動範圍,單位mm。

*注意:有(yǒu)效行程超過型錄上所列共振長(cháng)度時可(kě)能(néng)發生振動,應降低運轉速度,請參見「速度」項的說明。

⑤平台型式:

目前均為(wèi)标準負荷設計。如有(yǒu)超過表列額定動負載或最大可(kě)搬重量的重負荷需求,請洽HIWIN業務(wù),提供特殊規劃

設計服務(wù)。

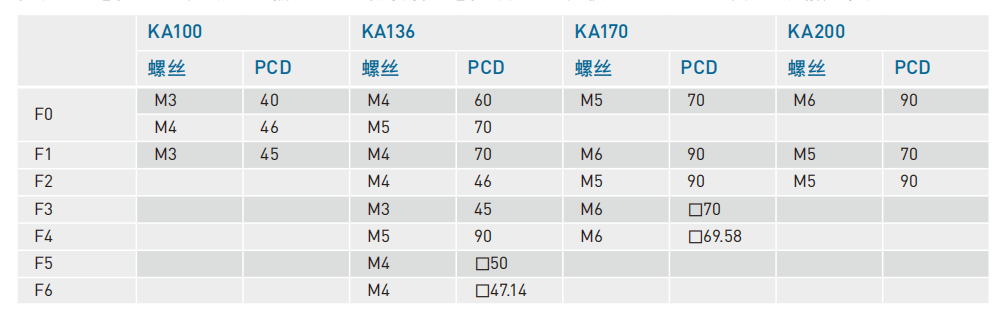

⑥電(diàn)機法蘭:

标準型為(wèi)電(diàn)機直接式,以聯軸器驅動。為(wèi)配合各型電(diàn)機的安(ān)裝(zhuāng),提供轉接法蘭, 基本安(ān)裝(zhuāng)規格如下表。

FD:電(diàn)機下接式,以皮帶輪驅動。 FL:電(diàn)機左側接式,以皮帶輪驅動。

FI:電(diàn)機内藏式,以聯軸器驅動。 FR:電(diàn)機右側接式,以皮帶輪驅動。

各法蘭相關尺寸請參閱附錄。

⑦鋁護蓋:

标準件均附鋁護蓋。∪:表示不裝(zhuāng)護蓋。

⑧極限開關:

表列數種供選擇。若拟采用(yòng)其他(tā)型式,請洽HIWIN業務(wù)注明。

⑨電(diàn)機:

無記号:不附電(diàn)機。若由客戶自備電(diàn)機,HIWIN代客組裝(zhuāng),請洽HIWIN業務(wù)注明。

M :附電(diàn)機。常用(yòng)電(diàn)機型式請參閱附錄,如拟采用(yòng)其他(tā)型式,請洽HIWIN業務(wù)注明。

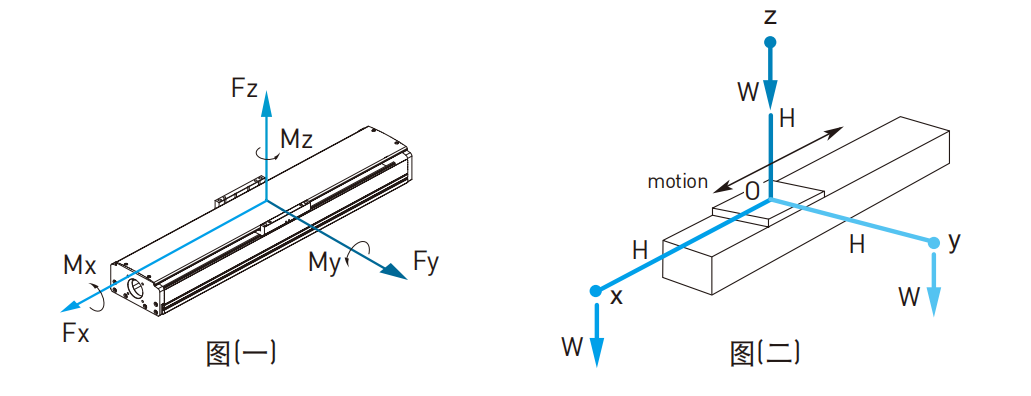

額定動負載:

額定動負載方向定義如圖(-)所示。型錄中(zhōng)表列額定動負載( Fy, Fz, Mx, My, Mz)是相對于KA行走10,000Km的壽

命,為(wèi)确保KA長(cháng)期使用(yòng),建議盡可(kě)能(néng)在表列負載範圍内使用(yòng)。

圖(二)中(zhōng),負載作(zuò)用(yòng)位置為(wèi)滑台安(ān)裝(zhuāng)平面的中(zhōng)心。但是,實際使用(yòng)時負載重心的位置未必在此中(zhōng)心點上,如果離

開中(zhōng)心太遠(yuǎn)可(kě)能(néng)引起振動、過大的力矩、或動作(zuò)反應遲緩。

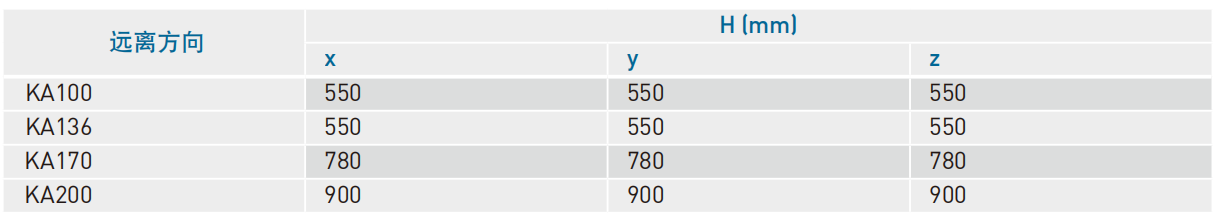

為(wèi)了避免這些不良現象,負載重心(W)遠(yuǎn)離滑台中(zhōng)心(0)的距離(H)請盡可(kě)能(néng)維持在下表範圍内。

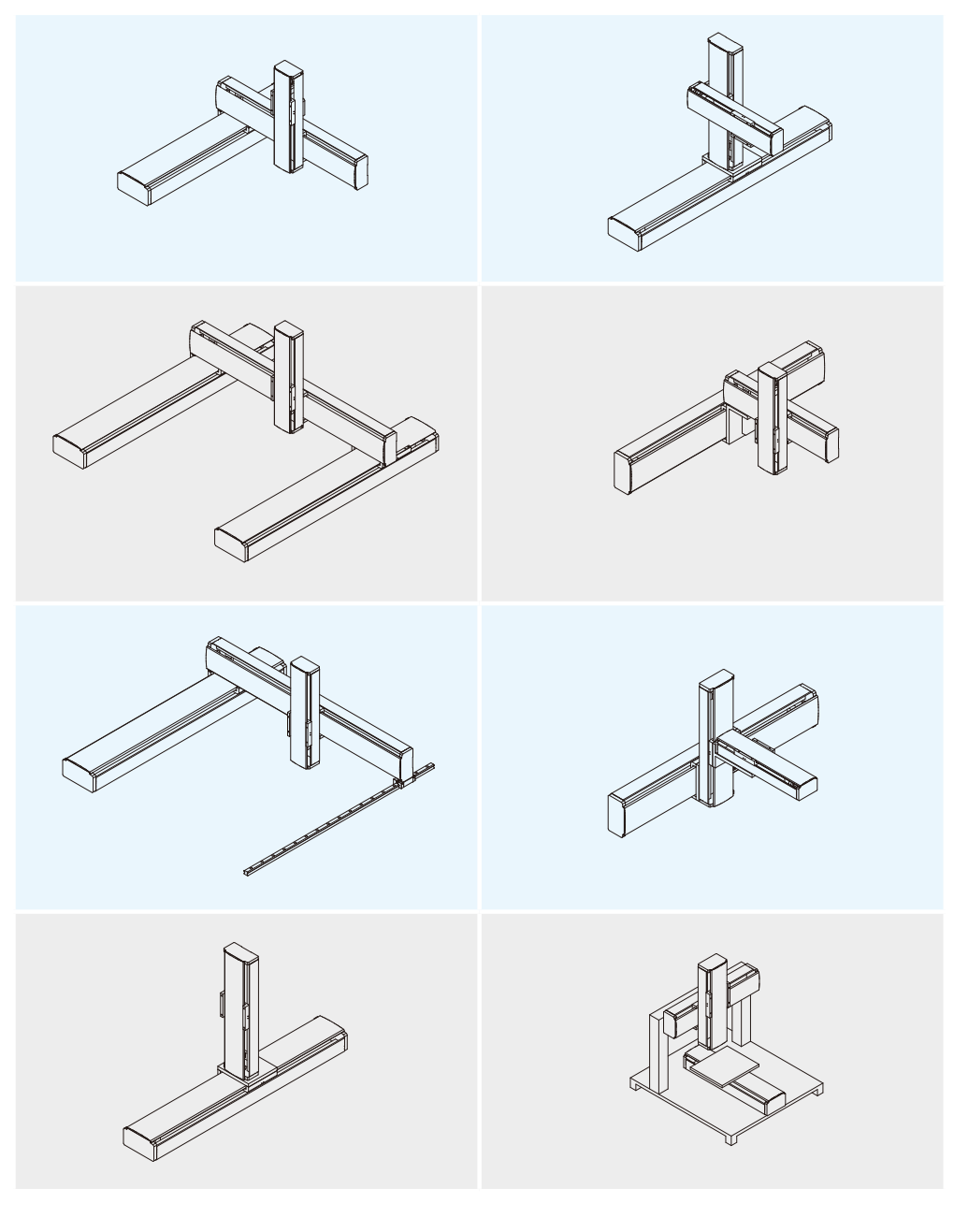

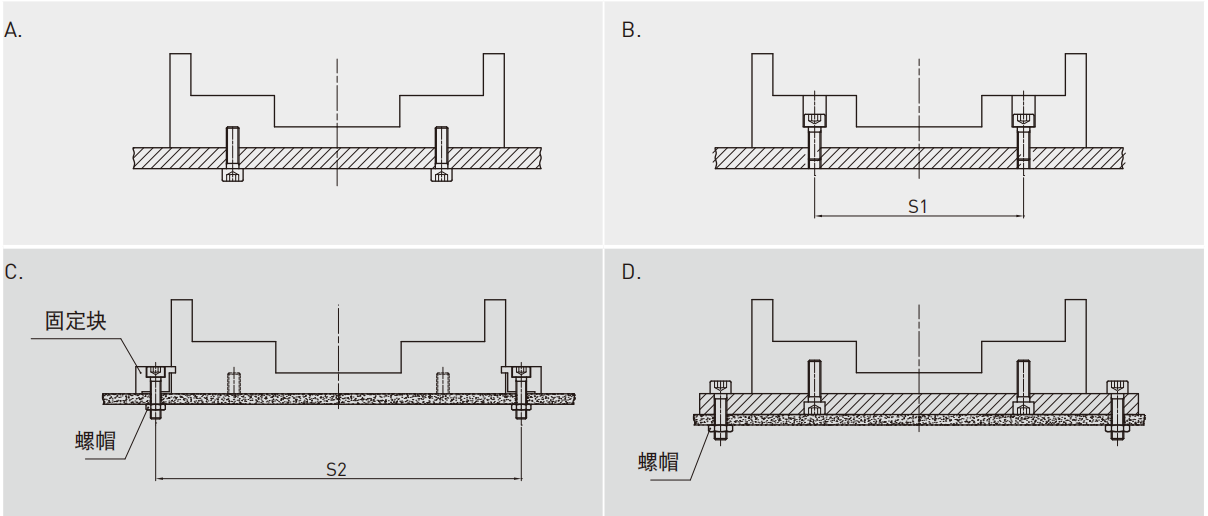

安(ān)裝(zhuāng)方式:

KA系列産(chǎn)品安(ān)裝(zhuāng)方式有(yǒu)下列數種,如圖所示。

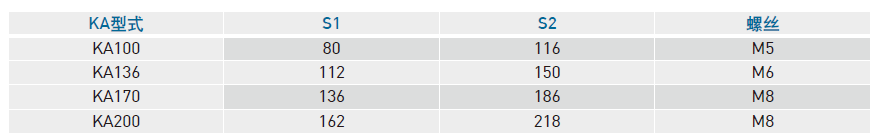

其中(zhōng),B和C型的「上鎖式」,螺絲間距(S1)如下:

HIWIN上銀直線(xiàn)模組KA1005P-450A-FR

HIWIN上銀KA100-F0直接式型号:

KA1005C-100A-F0,KA1005P-100A-F0,KA10010C-100A-F0,KA10010P-100A-F0,KA10020C-100A-F0,KA10020P-100A-F0

KA1005C-150A-F0,KA1005P-150A-F0,KA10010C-150A-F0,KA10010P-150A-F0,KA10020C-150A-F0,KA10020P-150A-F0

KA1005C-200A-F0,KA1005P-200A-F0,KA10010C-200A-F0,KA10010P-200A-F0,KA10020C-200A-F0,KA10020P-200A-F0

KA1005C-250A-F0,KA1005P-250A-F0,KA10010C-250A-F0,KA10010P-250A-F0,KA10020C-250A-F0,KA10020P-250A-F0

KA1005C-300A-F0,KA1005P-300A-F0,KA10010C-300A-F0,KA10010P-300A-F0,KA10020C-300A-F0,KA10020P-300A-F0

KA1005C-350A-F0,KA1005P-350A-F0,KA10010C-350A-F0,KA10010P-350A-F0,KA10020C-350A-F0,KA10020P-350A-F0

KA1005C-400A-F0,KA1005P-400A-F0,KA10010C-400A-F0,KA10010P-400A-F0,KA10020C-400A-F0,KA10020P-400A-F0

KA1005C-450A-F0,KA1005P-450A-F0,KA10010C-450A-F0,KA10010P-450A-F0,KA10020C-450A-F0,KA10020P-450A-F0

KA1005C-500A-F0,KA1005P-500A-F0,KA10010C-500A-F0,KA10010P-500A-F0,KA10020C-500A-F0,KA10020P-500A-F0

KA1005C-550A-F0,KA1005P-550A-F0,KA10010C-550A-F0,KA10010P-550A-F0,KA10020C-550A-F0,KA10020P-550A-F0

KA1005C-600A-F0,KA1005P-600A-F0,KA10010C-600A-F0,KA10010P-600A-F0,KA10020C-600A-F0,KA10020P-600A-F0

KA1005C-650A-F0,KA1005P-650A-F0,KA10010C-650A-F0,KA10010P-650A-F0,KA10020C-650A-F0,KA10020P-650A-F0

KA1005C-700A-F0,KA1005P-700A-F0,KA10010C-700A-F0,KA10010P-700A-F0,KA10020C-700A-F0,KA10020P-700A-F0

KA1005C-750A-F0,KA1005P-750A-F0,KA10010C-750A-F0,KA10010P-750A-F0,KA10020C-750A-F0,KA10020P-750A-F0

KA1005C-800A-F0,KA1005P-800A-F0,KA10010C-800A-F0,KA10010P-800A-F0,KA10020C-800A-F0,KA10020P-800A-F0

KA1005C-850A-F0,KA1005P-850A-F0,KA10010C-850A-F0,KA10010P-850A-F0,KA10020C-850A-F0,KA10020P-850A-F0

KA1005C-900A-F0,KA1005P-900A-F0,KA10010C-900A-F0,KA10010P-900A-F0,KA10020C-900A-F0,KA10020P-900A-F0

KA1005C-950A-F0,KA1005P-950A-F0,KA10010C-950A-F0,KA10010P-950A-F0,KA10020C-950A-F0,KA10020P-950A-F0

KA1005C-1000A-F0,KA1005P-1000A-F0,KA10010C-1000A-F0,KA10010P-1000A-F0,KA10020C-1000A-F0,KA10020P-1000A-F0

KA1005C-1050A-F0,KA1005P-1050A-F0,KA10010C-1050A-F0,KA10010P-1050A-F0,KA10020C-1050A-F0,KA10020P-1050A-F0

HIWIN上銀KA100-FL左接式型号:

KA1005C-100A-FL,KA1005P-100A-FL,KA10010C-100A-FL,KA10010P-100A-FL,KA10020C-100A-FL,KA10020P-100A-FL

KA1005C-150A-FL,KA1005P-150A-FL,KA10010C-150A-FL,KA10010P-150A-FL,KA10020C-150A-FL,KA10020P-150A-FL

KA1005C-200A-FL,KA1005P-200A-FL,KA10010C-200A-FL,KA10010P-200A-FL,KA10020C-200A-FL,KA10020P-200A-FL

KA1005C-250A-FL,KA1005P-250A-FL,KA10010C-250A-FL,KA10010P-250A-FL,KA10020C-250A-FL,KA10020P-250A-FL

KA1005C-300A-FL,KA1005P-300A-FL,KA10010C-300A-FL,KA10010P-300A-FL,KA10020C-300A-FL,KA10020P-300A-FL

KA1005C-350A-FL,KA1005P-350A-FL,KA10010C-350A-FL,KA10010P-350A-FL,KA10020C-350A-FL,KA10020P-350A-FL

KA1005C-400A-FL,KA1005P-400A-FL,KA10010C-400A-FL,KA10010P-400A-FL,KA10020C-400A-FL,KA10020P-400A-FL

KA1005C-450A-FL,KA1005P-450A-FL,KA10010C-450A-FL,KA10010P-450A-FL,KA10020C-450A-FL,KA10020P-450A-FL

KA1005C-500A-FL,KA1005P-500A-FL,KA10010C-500A-FL,KA10010P-500A-FL,KA10020C-500A-FL,KA10020P-500A-FL

KA1005C-550A-FL,KA1005P-550A-FL,KA10010C-550A-FL,KA10010P-550A-FL,KA10020C-550A-FL,KA10020P-550A-FL

KA1005C-600A-FL,KA1005P-600A-FL,KA10010C-600A-FL,KA10010P-600A-FL,KA10020C-600A-FL,KA10020P-600A-FL

KA1005C-650A-FL,KA1005P-650A-FL,KA10010C-650A-FL,KA10010P-650A-FL,KA10020C-650A-FL,KA10020P-650A-FL

KA1005C-700A-FL,KA1005P-700A-FL,KA10010C-700A-FL,KA10010P-700A-FL,KA10020C-700A-FL,KA10020P-700A-FL

KA1005C-750A-FL,KA1005P-750A-FL,KA10010C-750A-FL,KA10010P-750A-FL,KA10020C-750A-FL,KA10020P-750A-FL

KA1005C-800A-FL,KA1005P-800A-FL,KA10010C-800A-FL,KA10010P-800A-FL,KA10020C-800A-FL,KA10020P-800A-FL

KA1005C-850A-FL,KA1005P-850A-FL,KA10010C-850A-FL,KA10010P-850A-FL,KA10020C-850A-FL,KA10020P-850A-FL

KA1005C-900A-FL,KA1005P-900A-FL,KA10010C-900A-FL,KA10010P-900A-FL,KA10020C-900A-FL,KA10020P-900A-FL

KA1005C-950A-FL,KA1005P-950A-FL,KA10010C-950A-FL,KA10010P-950A-FL,KA10020C-950A-FL,KA10020P-950A-FL

KA1005C-1000A-FL,KA1005P-1000A-FL,KA10010C-1000A-FL,KA10010P-1000A-FL,KA10020C-1000A-FL,KA10020P-1000A-FL

KA1005C-1050A-FL,KA1005P-1050A-FL,KA10010C-1050A-FL,KA10010P-1050A-FL,KA10020C-1050A-FL,KA10020P-1050A-FL

HIWIN上銀KA100-FR右接式型号:

KA1005C-100A-FR,KA1005P-100A-FR,KA10010C-100A-FR,KA10010P-100A-FR,KA10020C-100A-FR,KA10020P-100A-FR

KA1005C-150A-FR,KA1005P-150A-FR,KA10010C-150A-FR,KA10010P-150A-FR,KA10020C-150A-FR,KA10020P-150A-FR

KA1005C-200A-FR,KA1005P-200A-FR,KA10010C-200A-FR,KA10010P-200A-FR,KA10020C-200A-FR,KA10020P-200A-FR

KA1005C-250A-FR,KA1005P-250A-FR,KA10010C-250A-FR,KA10010P-250A-FR,KA10020C-250A-FR,KA10020P-250A-FR

KA1005C-300A-FR,KA1005P-300A-FR,KA10010C-300A-FR,KA10010P-300A-FR,KA10020C-300A-FR,KA10020P-300A-FR

KA1005C-350A-FR,KA1005P-350A-FR,KA10010C-350A-FR,KA10010P-350A-FR,KA10020C-350A-FR,KA10020P-350A-FR

KA1005C-400A-FR,KA1005P-400A-FR,KA10010C-400A-FR,KA10010P-400A-FR,KA10020C-400A-FR,KA10020P-400A-FR

KA1005C-450A-FR,KA1005P-450A-FR,KA10010C-450A-FR,KA10010P-450A-FR,KA10020C-450A-FR,KA10020P-450A-FR

KA1005C-500A-FR,KA1005P-500A-FR,KA10010C-500A-FR,KA10010P-500A-FR,KA10020C-500A-FR,KA10020P-500A-FR

KA1005C-550A-FR,KA1005P-550A-FR,KA10010C-550A-FR,KA10010P-550A-FR,KA10020C-550A-FR,KA10020P-550A-FR

KA1005C-600A-FR,KA1005P-600A-FR,KA10010C-600A-FR,KA10010P-600A-FR,KA10020C-600A-FR,KA10020P-600A-FR

KA1005C-650A-FR,KA1005P-650A-FR,KA10010C-650A-FR,KA10010P-650A-FR,KA10020C-650A-FR,KA10020P-650A-FR

KA1005C-700A-FR,KA1005P-700A-FR,KA10010C-700A-FR,KA10010P-700A-FR,KA10020C-700A-FR,KA10020P-700A-FR

KA1005C-750A-FR,KA1005P-750A-FR,KA10010C-750A-FR,KA10010P-750A-FR,KA10020C-750A-FR,KA10020P-750A-FR

KA1005C-800A-FR,KA1005P-800A-FR,KA10010C-800A-FR,KA10010P-800A-FR,KA10020C-800A-FR,KA10020P-800A-FR

KA1005C-850A-FR,KA1005P-850A-FR,KA10010C-850A-FR,KA10010P-850A-FR,KA10020C-850A-FR,KA10020P-850A-FR

KA1005C-900A-FR,KA1005P-900A-FR,KA10010C-900A-FR,KA10010P-900A-FR,KA10020C-900A-FR,KA10020P-900A-FR

KA1005C-950A-FR,KA1005P-950A-FR,KA10010C-950A-FR,KA10010P-950A-FR,KA10020C-950A-FR,KA10020P-950A-FR

KA1005C-1000A-FR,KA1005P-1000A-FR,KA10010C-1000A-FR,KA10010P-1000A-FR,KA10020C-1000A-FR,KA10020P-1000A-FR

KA1005C-1050A-FR,KA1005P-1050A-FR,KA10010C-1050A-FR,KA10010P-1050A-FR,KA10020C-1050A-FR,KA10020P-1050A-FR

相關标簽:KA1005P-450A-FR上銀模組上銀直線(xiàn)模組,上銀KA模組,上銀KA直線(xiàn)模組

上一篇:KA1005P-500A-FR

下一篇:KA1005P-400A-FR